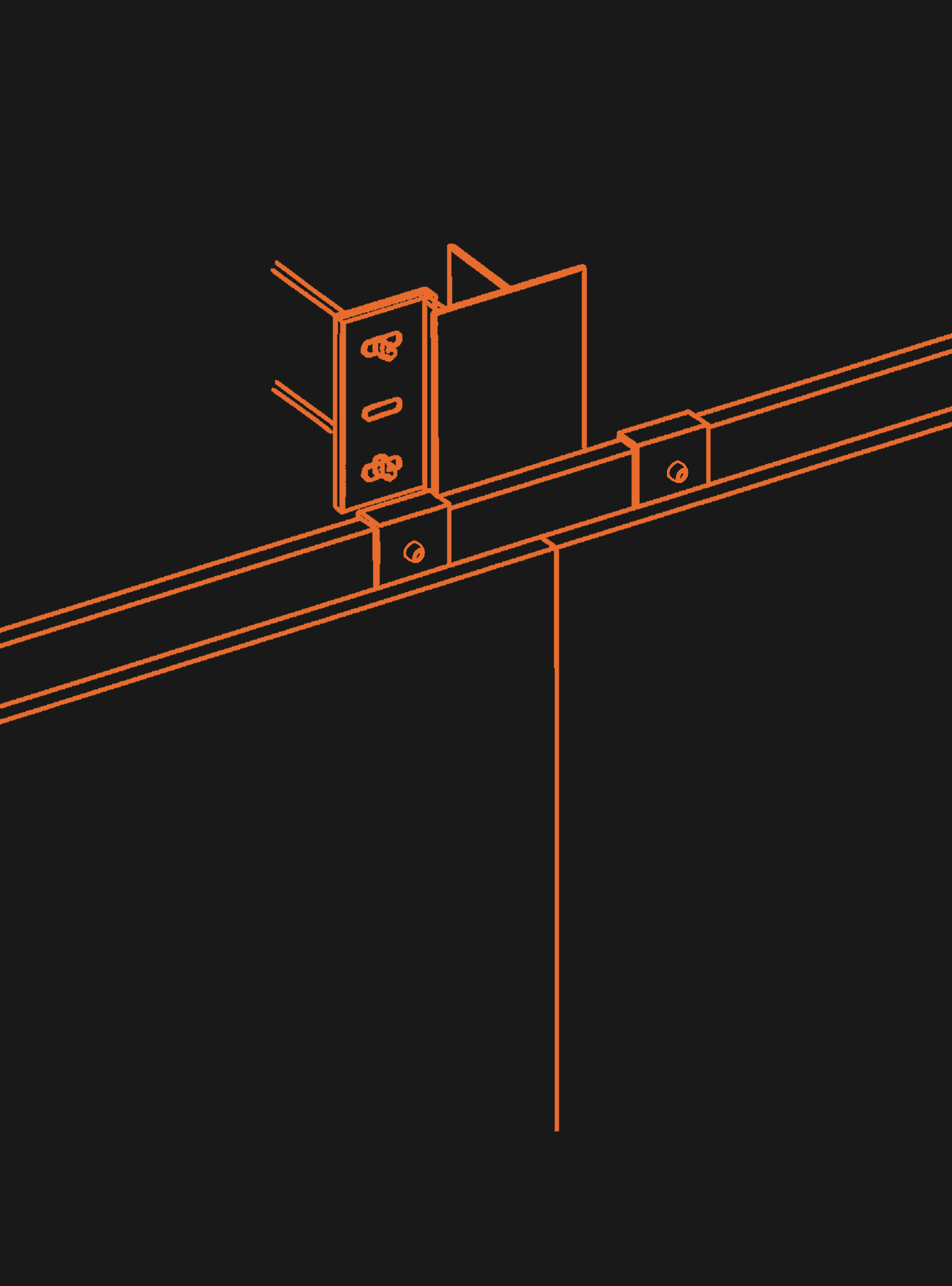

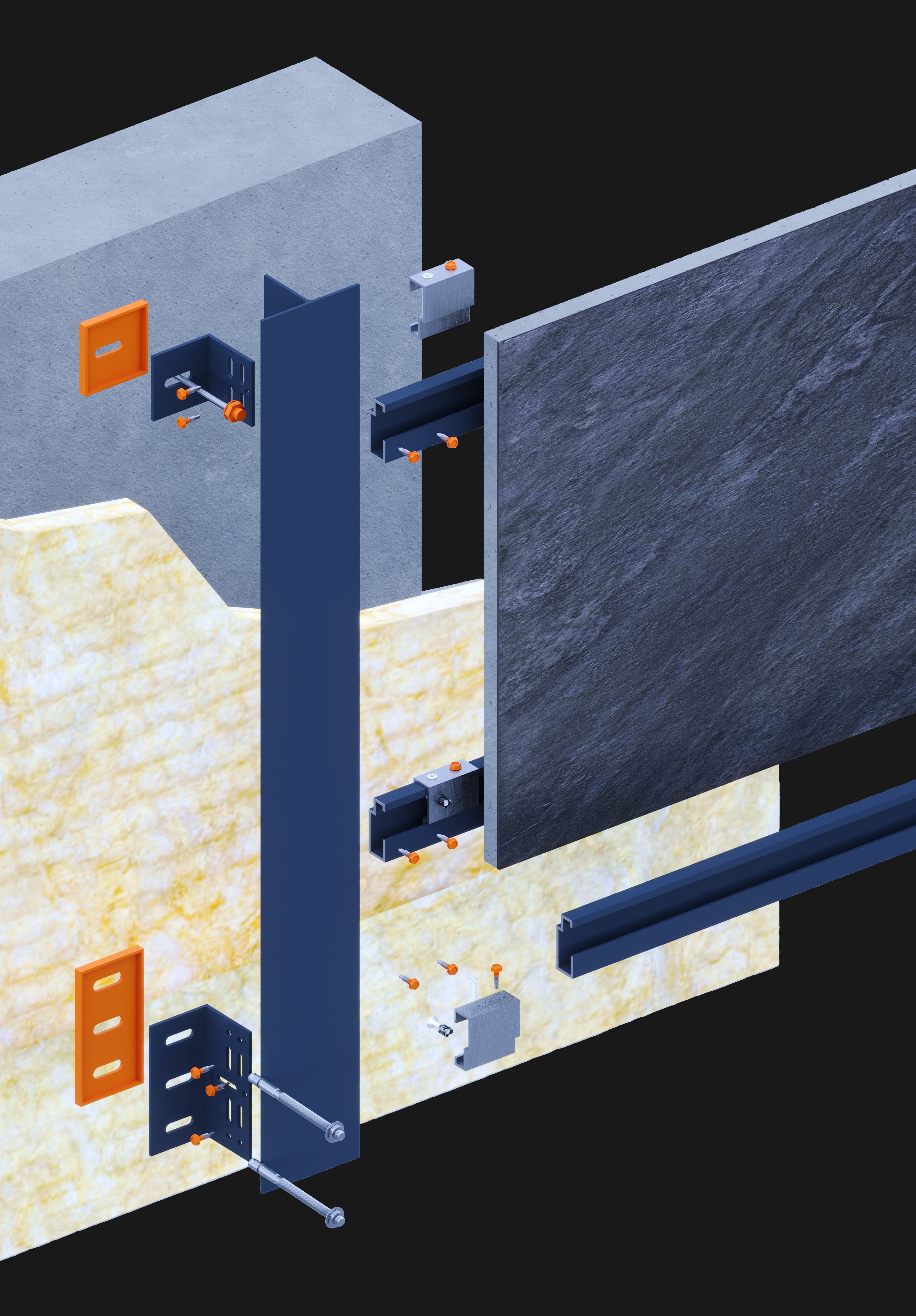

Designed for 12–20 mm porcelain slabs, this mechanical system uses undercut anchors drilled into the slab’s back face and fixed to a double-layer aluminum substructure. It enables concealed, secure installation with a clean, modern appearance.The system supports vertical and horizontal installation of large-format slabs up to 1620 × 3240 mm. Anchor placement is based on slab thickness, weight, and project requirements, with drilling performed on-site per supplier guidelines. Suitable for façades requiring high strength and flexibility, it allows precise alignment and adjustments during installation. A dry, adhesive-free method, it ensures long-term durability and structural safety.

Download Catalog