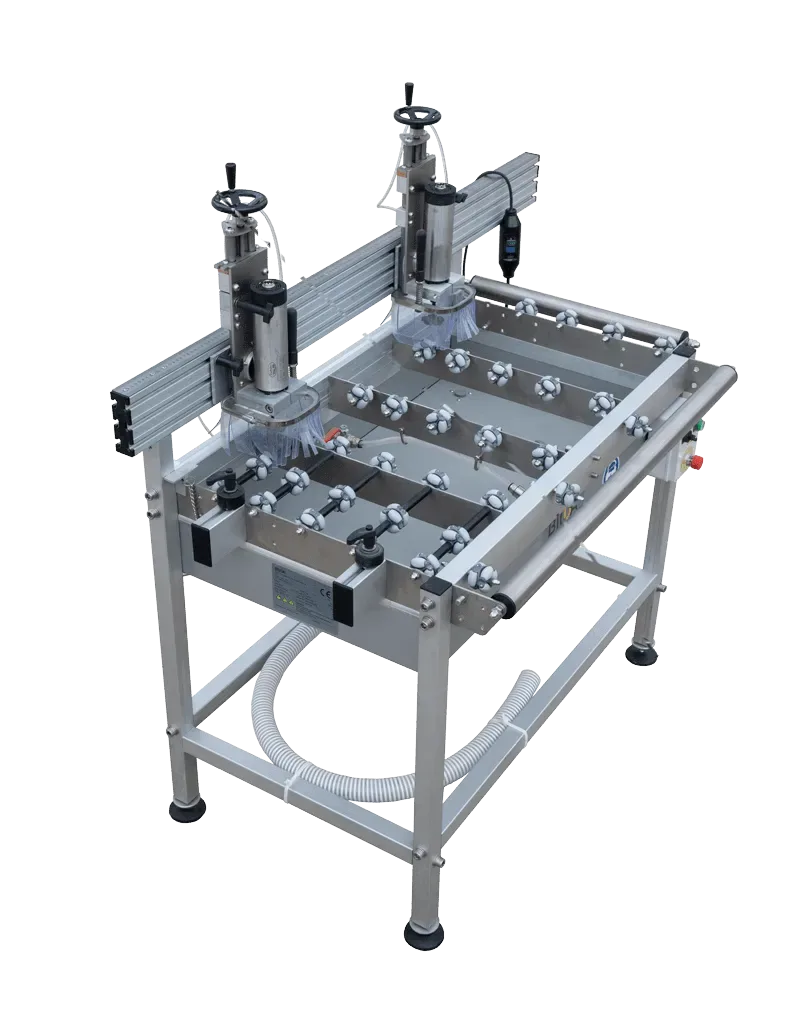

The 1200 Double-Head Automatic Slotting Machine is engineered for high-speed, double-sided grooving of porcelain, ceramic, and façade cladding panels. With a processing range of 250–1200 mm and thickness up to 50 mm, it combines robust stainless steel and aluminum construction with precision components like TBI linear guides, SKF bearings, and Schneider Electric controls. This CE-certified machine offers fast processing speeds (2–4 m/min), adjustable machining heads, and optional drilling conversion—making it an ideal solution for efficient, accurate slotting in high-volume production environments.

Download Catalog